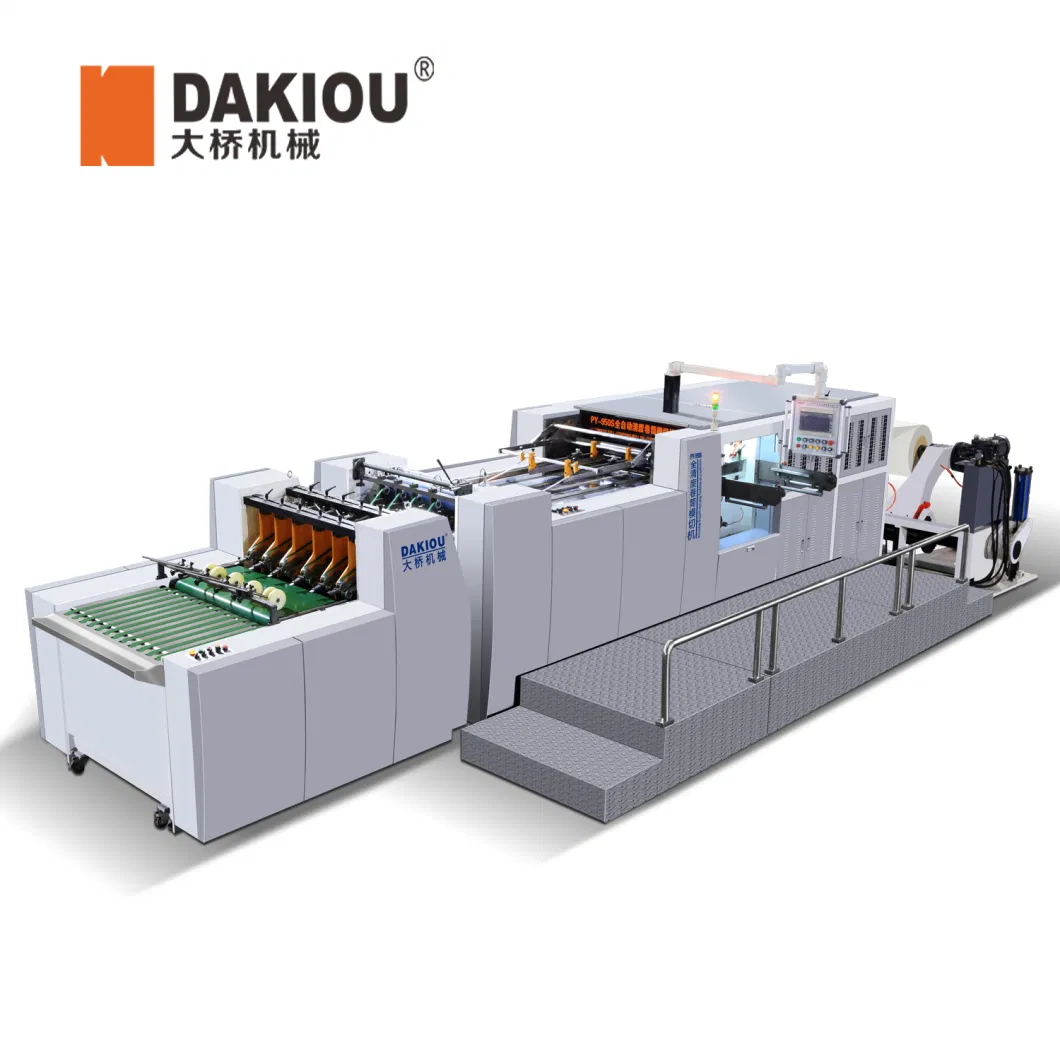

Py

Description

Basic Info.

| Model NO. | PY-950S |

| Package Size | 10000X4000X2000 |

| Paper Material | 120-600G/M2 |

| Warranty | 1year |

| Power | 30kw |

| Transport Package | Wooden Case |

| Trademark | Dakiou |

| Origin | China |

Product Description

Products description:PY Automatic Full-stripping Roll Die Cutting Machine can complete full steps from roll to finished product including die cutting, creasing, stripping and collection. It is an ideal equipment for producing paper cups fan, paper boxes, cards etc of post-press packaging.Easy and safety operation, High efficiency.

Technical Specification:| Type: | PY-950S |

| Cut Precision: | ± 0.10mm |

| Production capacity: | 90-150times/min |

| Paper Convey Width: | 950 x540mm Or 950 x640mm |

| Max Roll paper diameter: | 950mm |

| Suitable Material: | 120-600g/m2 Pe coated paper |

| Total Power: | 30KW |

| Total Weight: | 12000kgs |

| Maximum cutting size: | 950 x540mm |

| Maximum Pressure: | 350T |

| Overall Dimension: | 10000 x4000 x 2000 mm |

| Working Air Source: | 0.6mpa |

Main feature:

1.The normal working,speed is 90-120times per minute. It has the ability to die-cutting, creasing, sheeting, stripping and collecting.

2.Imported servo motor driving, imported color sensor recognizition, new sheeting design(the old type use the rod flapping to sheeting),full-stripping by pinheads, automatic stack collecting.

3.Worm wheel and worm transmission system ensures the powerful and steady pressure. Lubricating with oil circulation and alarming when lack of oil.

4.Equipped shaftless unwinding unit, and use the pneumatic brake and multilevel tension controller to control roll paper unwinding.

5.Use PLC as its control center, in coordination with original LG electrical elements from KOREA, original Panasonic sensor from JAPAN, original SHAKO and MINGMAN pneumatic parts.

6.Alarming system: lubrication blocking alarming, paper feeding blocking alarming, limit alarming, stripping failed alarming.

7.The main body is much stronger. We use the more thick steel board and cast iron board instead of the normal one.

Advantage and improvement:

1.Machine Host. New design: Worm and Worm wheel together with crankshaft same as the sheet die-cutting machine. The previous design: off-center shaft.

2.Pressure Adjusted. New design: The pressure is automatic adjusted through the motor to control the four feet by HMI.And the pressure can be shown in the HMI.It is very convenient and accurate. The previous design: manual adjusted through gear wheel or the screw.

3.Oil circuit. New design: The outside oil circuit adds a filter to clear the oil and a flow switch to monitor lacking oil. The previous oil circuit is crude and confused.(the first machinery equips with alarming of oil lacked)

4.Positioning block in movable platform we add one more positioning block in movable platform. It makes the pressure of the platform more stable, and endurable.

5.The main driving parts in host is protected by the lubrication system. If the data shows problem, the machine will stop and alarming. Then you must check the driving parts

6.Air cylinder paper pressure system. In front of the paper feeding platform, we add the air cylinder paper pressure system to ensure the paper convey more smoothly and quickly. We are the first one and the only one machinery who adds this system

7.PLC program:The new design: We make two PLC program to fit for the different quality of printing. Be more functional and accurate

8.Paper feeding balance regulator add new type paper feeding balance regulator to adjust he minor unbalance situation.

9.Paper damper. In order to avoid the paper shaking, we add one more damper to make the paper tractable. The paper leech on the damper when machine is running. So we can feed paper more stable and faster

10.Roll Paper Loading: The new design: the hydraulic cylinder pushes downward, so it is stronger than the previous design.

11.Paper blocked alarm system. The new design adds the alarm system to make the machine stop when paper feeding blocked.

FAQ:

1

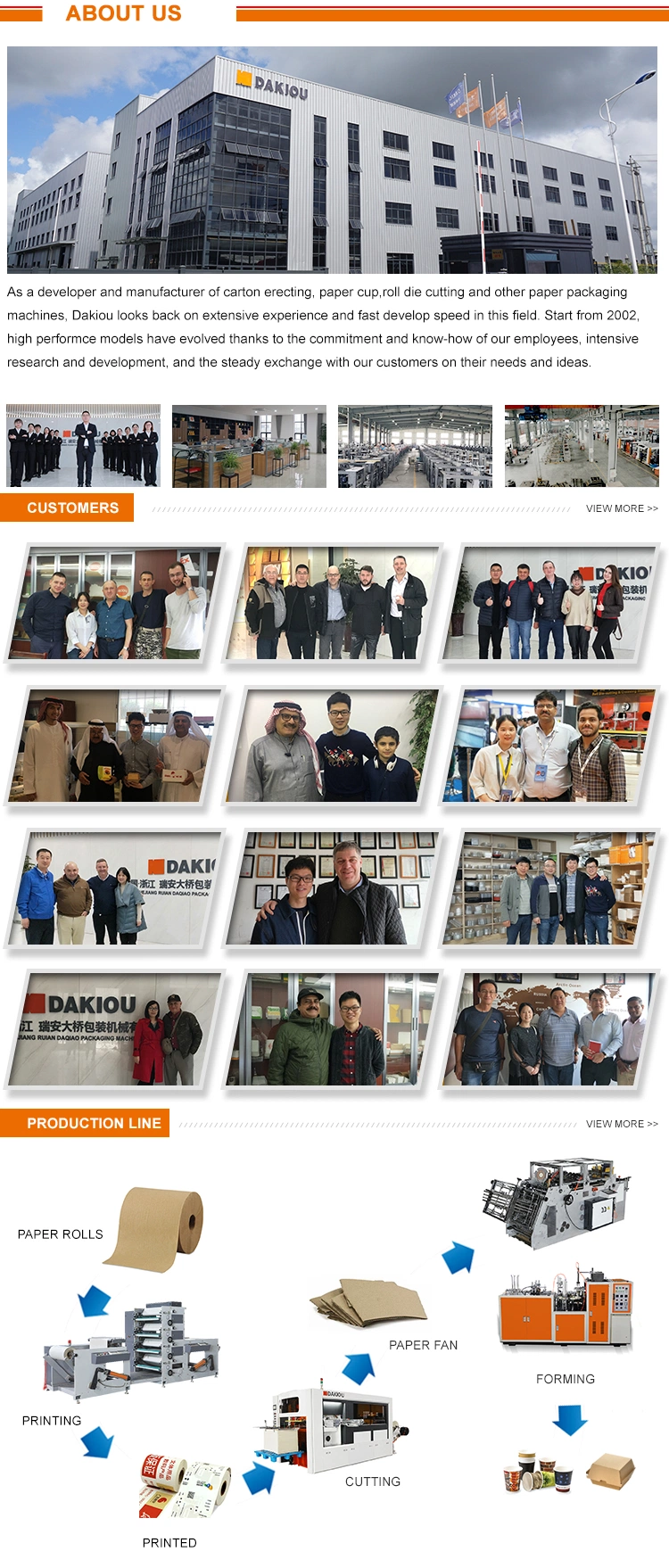

Q:Where is your factory? How can I get there?

A: We are located in Ruian City Wenzhou, Zhejiang Province.

To Wenzhou Longwan airport by Air, from Shanghai is about 45mins,from Guangzhou is about 1hr 50mins and from Hongkong is about 2hrs.We will pick up you in the airport.

2

Q:Can your machine be customized?

A: Your better improvement suggestions are highly appreciated. Almost all of our products can be customized, including the sizes, color, logo, package and so on.

3.Q :What's the OLD(order lead time)?

A: For our standard model machines is about 30days after receiving your deposit.

4. Q: How about your package?

A: Our machines are well wrapped by plastic film to be water proof first, then loading and fixing in a plywood case. If by FCL(full container loading) we might use the wooden pallet with plastic film wrapping, without plywood case.

Prev: Press Machine for High

Next: Rotary Damper Smart Door Lock Single Bidirectional Damping Gear Rotary Damper

Our Contact