Superior Quality CE Approved Paint Drying Room for Automobile

Superior Quality CE Approved Paint Drying Room for Automobile1.ADVANTAGES CE standard Full downdraught airflow High effi

Description

Basic Info.

| Model NO. | IT-L8 |

| Paint Mist Treatment | Dry-type |

| Condition | New |

| Empty Loaded Air Speed | 0.30m/S |

| Heats | 315kw Heat Exchanger |

| Air Volume | 35,000m3/H |

| Noise | <78 dB |

| Warranty | 2 Years |

| Inverter | Schneider |

| Maximum Working Temperature | 80 Celsius |

| Grids Carrying Capacity | 900kg/Wheel |

| Brightness | >1,500lux |

| Walls | 50mm Rock Wool Walls |

| Extraction | 350mm |

| Extraction Area | 32m2 |

| Plenum (Height) | 600mm |

| Transport Package | Cargo Loaded on Steel Frame Handled by Forklifts |

| Specification | 8000 X 4000 X 3000mm (L X W X H) |

| Trademark | INFITECH |

| Origin | Guangzhou, China |

| HS Code | 8419899090 |

| Production Capacity | 1000 Sets/Year |

Product Description

Superior Quality CE Approved Paint Drying Room for Automobile1.ADVANTAGES- CE standard

- Full downdraught airflow

- High efficiency generator unit

- Easy to use and maintain

- Long service time

- Lower operating costs

2.SPECIFICATIONS

| ITEMS | SPECIFICATIONS |

| Model | IT-SUPER-L8 car spray booth |

| Design standard | BS EN 13355: 2004+A1:2009 BS EN 60204: 2006+A1:2009 |

| Internal dimensions | 8000 X 4000 X 3000mm (L X W X H) |

| External dimensions | 8110 X 5760 X 4010mm (L X W X H) |

| Airflow | Full Downdraft |

| Plenum (height) | 600mm |

| Extraction | Through 350mm high raised basement |

| Extraction area | 32m2 |

| Grids carrying capacity | 900kg/wheel |

| Entrance door | 3400x2900mm (WxH), 1 set |

| Service door | 800x2000mm(WxH), 2 sets |

| Walls | 50mm rock wool walls |

| Ceiling lights (LED) | 10 sets, each 6 X 18W, 1,080W total |

| Sidewall lights (LED) | 10 sets, each 2 X 18W, 360W total |

| Brightness | >1,500LUX |

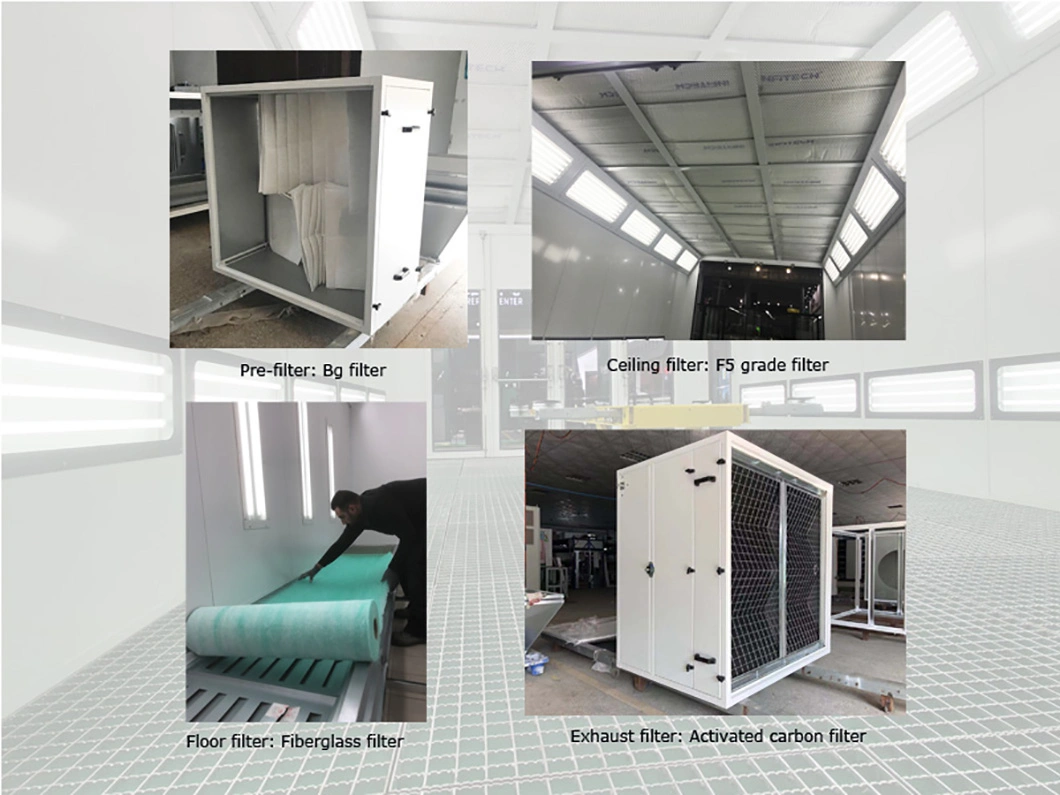

| Filters | Bag filter, high efficiency ceiling filter, floor filter, exhaust filter |

| Intake/Exhaust unit | Direct-type turbine fan, 2x11KW, SIEMENS motor |

| Air volume | 35,000m3/h |

| Empty loaded air speed | 0.30m/s |

| Heats | 315kw heat exchanger, RIELLO gas burner RS5D |

| Maximum working temperature | 80ºC |

| Controls | CE standard control box |

| Inverter | SCHNEIDER inverter |

| Rated power | 28KW |

3.FEATURES & APPLICATION

- With internal dimensions of 8000x4000x3000mm and wide opening entry door, IT-SUPER-L8 spray booth suits all car models. It is with full downdraft airflow, generally considered as the best airflow for auto refinish, creating superb condition for achieving perfect painting finish effect.

- 0.30m/s empty loaded air speed makes the booth ideal for spraying water-based paints.

- Low noise fan with SIEMENS motor ensure reliable operation and high performance.

- 315kw heating exchanger efficiency > 90%, less heating time and less energy consumption.

- With SCHNEIDER inverter, saves energy consumption of more than 30%.

- With the function of automatic pressure regulation.

AIRFLOW & BOOTH STRUCTURE

IT-SUPER-L8 is standard with full downdraft airflow. There is diffuser inside the 600mm high plenum for even air distribution. And in the 350mm high raised basement, it is also with diffuser device, i.e. perforated flaps. By adjusting the flaps, the air flow speed can be adjusted to achieve consistent airflow, which helps extract overspray, and avoid the accumulation of overspray inside the booth and on the walls.

OPTION

Different types of basement are available to suit different installation sites.

- Metal basement in the ground

- Pit with full grids

- Pit with two rows of grids

- Raised metal basement with internal pneumatic ramp

- Raised metal basement with internal fixed ramp

- 4-wing product entry door: 3400x2900mm, observation window: 500x1995mm

- Inclined ceiling and vertical sidewall lights create superb shadow-free workspace

- High performance low noise fan & SIEMENS motor

- Cylinder-drive cycle damper, with limit switch for verifying if the damper is at the correct position for spraying phase or baking phase

- 315KW heat exchanger, RIELLO gas burner RS5D (two stage)

OPTION

- Diesel burner

- Direct gas fired heating system

- Electric heating

CONTROL

- Basic functions: spraying, heating spraying, flash, baking, cooling

- Safety functions: emergency stop, over-heat alarm, failure alarm, fans interlock with heating system

- SCHNEIDER inverter saves more than 30% energy

- With stack light indicating the working phase inside the booth

- Main electrical components: SCHNEIDER brand

UPGRADE

- Innovative touch screen control

| Item | Specification |

| Pre-filter | Bag filter |

| Ceiling filter | High efficiency F5 grade filter |

| Floor filter | Fiberglass paint arrestor filter |

| Extract filter | Activated carbon filter |

FAQQ: What is the MOQ?

A: The minimum order quantity is 1 set.

Q: How long does it take you to deliver?

A: For standard spray booth, it takes us approx. 20 days for production after receiving the advance payment. For the shipping schedule, it depends on which port we shall deliver the cargo to. And we need to check the sailing schedule case by case.

Q: What is the voltage? Can you follow the supplied voltage?

A: Our standard voltage is 380V, 50Hz, 3ph. Certainly, we can follow the voltage supplied by you. However, kindly be advised that the production lead time of SIEMENS motor with non-standard voltage is longer than 380V SIEMENS motor as the motor supplier does not keep stock of motors with non-standard voltage here, and they need time to customize for us.

Q: How do I purchase the spray booth from you?

A: First of all, send us the inquiry. If there is any specific request, tell us.

Then we will work out the offer for you.

For standard booth, we can submit quotation shortly after receiving your inquiry. For non-standard projects, it takes about 2-3 working days for us to work on the design and complete the offer.

Then after the offer is approved by you, we will make pro-forma invoice for you to make the advance payment.

And we proceed with final design and production, and load and ship the cargo after receiving the balance payment.

You will be provided with complete set of installation instructions files for installation guidance purpose.

Q: How can I pay you?

A: The preferred payment terms is 50% deposit upon order confirmation by T/T, and balance before shipment. At special request, we can also accept payment by L/C, please talk to Infitech sales engineers for more information.

Q: How do you pack and ship the spray booth?

A: The spray booth is generally delivered in various sub components palletized and in different packaging. In some cases the components are systematized loose. Labels are glued on the components for you to identify. In the meantime, you will receive detailed packing list so you can check the cargo upon the packing list upon delivery.

The spray booth is usually shipped in containers by sea.

For standard spray booth model IT-SUPER-L8, it has to be loaded and shipped in 1x40GP container.

Q: What is the warranty?

A: 2-year warranty.

Q: How to maintain the painting booths?

A: You will be provided with maintenance instructions, according to which you can prepare the maintenance schedule and carry out regular maintenance.

Prev: Automatic Lignomat Wood Dryer Booth Kiln Dry Room Wood Drying Chambertimber Drying Kiln Chamber

Next: Drying Chamber for Wood 40cmb Wood Baking Oven Customed Design Timber Drying Equipments

Our Contact

Send now